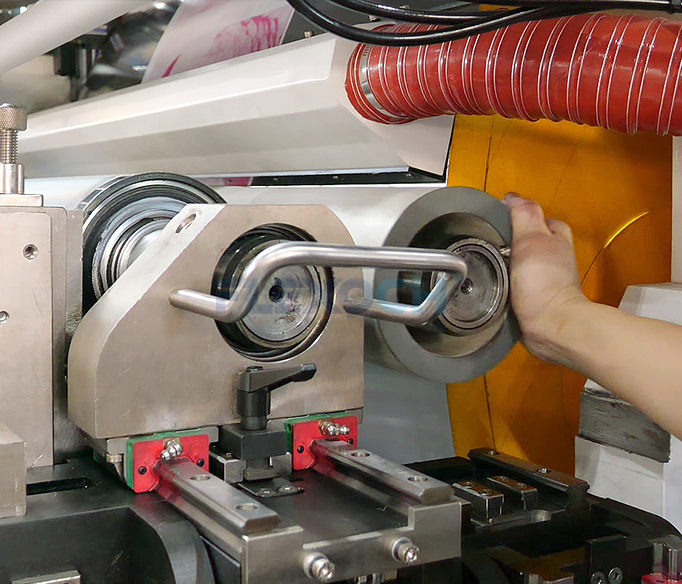

1.Iyi CI flexo press inoshandisa sleeve yekushandura hurongwa hwekukurumidza kushandura mapepa ekudhinda uye anilox rolls. Izvi zvinoderedza basa-kuchinja nguva, kuderedza mutengo wemidziyo, uye kurerutsa mashandiro.

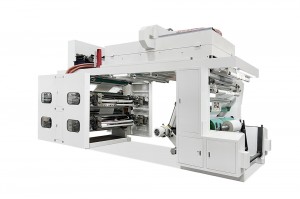

2.Iyo inoratidzira yepamusoro-performance servo unwinding / rewinding uye yakarurama tension control algorithm. Iyo sisitimu inochengetedza kugadzikana kwewebhu tension panguva yekumhanyisa, kushanda, uye kuderedza, kudzivirira kutanga / kumira kutambanudza kana kuunyana kwepamusoro-chaiyo prints.

3.Yakavakwa mukati neBST vision inspection system, iyi CI flexographic printing machine monitors print quality in real time. Iyo inongoona hurema uye inogadzirisa kunyoreswa, ichidzikisa kuvimba neruzivo rwevashandisi uye kuderedza kutambisa zvinhu.

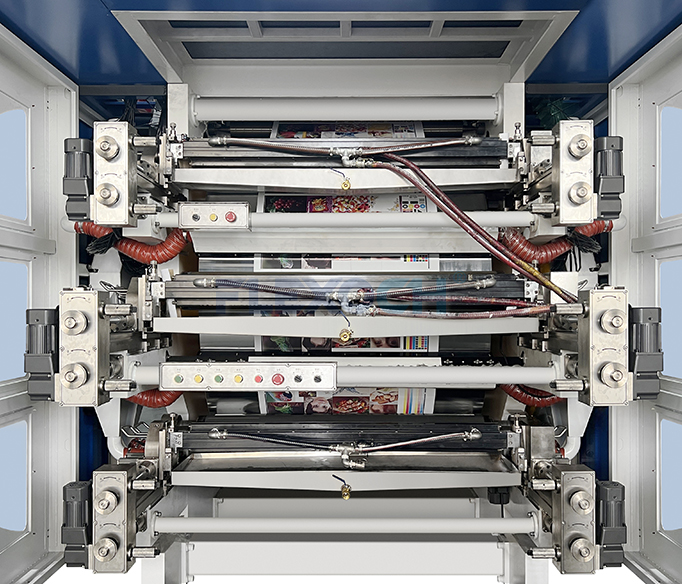

4.Zvose zvinodhinda zvikamu zvakanyatsorongeka zvakapoteredza imwe central impression cylinder. Izvi zvinodzikamisa substrate tension, inodzivirira kudhinda misalignment, uye inovimbisa ultra-chaiyo yakawanda-mavara kunyoreswa.